The SERVO.D is a single axis positioning unit for axis control and quick changeover positioning. Consisting of a brushless motor, gear reducer, PID motor control, position transducer and fieldbus interface in one compact unit.

Main Features:

- Integrated positioning unit.

- Torque rating 4Nm.

- MODBUS RTU, CANopen, or PROFIBUS DP fieldbus.

- Potentiometer with gear set for multi-turn absolute positioning.

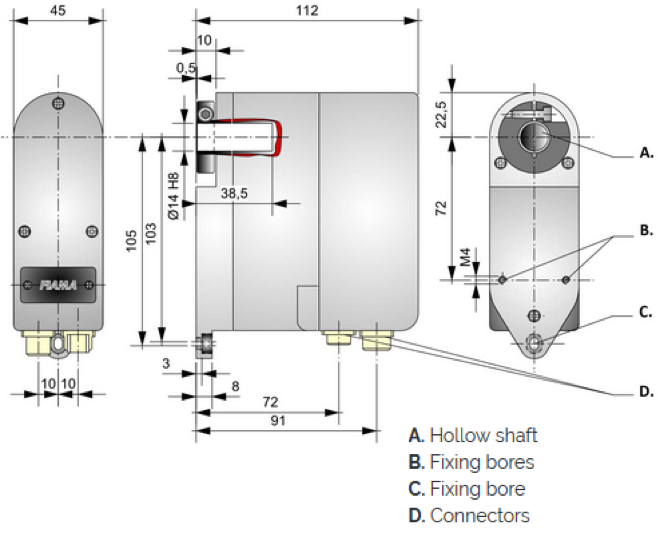

- Hollow bore design ø14mm.

On request:

- IP66 rated version.

- Electrical connectors.

Product features

| Motor torque | 4Nm |

|---|---|

| Shaft Sizes | Ø14mm |

| Fieldbus | MODBUS RTU, CANopen, or PROFIBUS DP |